How Bracu Estate Produces Award-Winning Olive Oil

Learn about the process behind Bracu Estate’s premium quality olive oil.

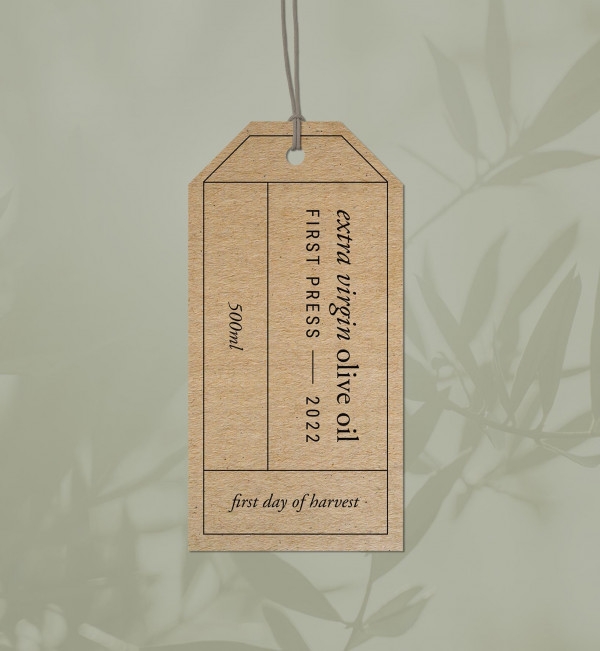

With 27,000 trees planted in the ground, Bracu Estate is by far New Zealand’s largest privately owned olive grove. But running such a large operation doesn’t mean there’s any drop-off in quality. In fact, it’s quite the opposite. From the olives to the environment, Bracu Estate’s commitment to producing the highest quality outcomes is evident throughout their operations. And with First Day of Harvest 2022 Extra Virgin Oilve Oil now available for pre-order, you can be certain that you’re getting the very best locally produced olive oil. But how does it all come together?

THE OLIVES

VARIETIES

Olive varieties on the Estate include Leccino and Frantoio from Tuscany, Carolea from Southern Italy, Picual, Kalamata and Koroneiki from Greece, along with the Pendolino for pollination and J5, a traditional local variety grown in New Zealand for more than 180 years.

POLLINATION

Because olive flowers aren’t sweet, bees are not attracted to them. While the Frantoio and J5 olive trees are self-pollinating, varieties such as Leccino, Picual, Koroneiki, Kalamata, Carolea and Pendolino rely on air pollination. They cross pollinate over a 10–14-day period from the end of November to beginning of December.

LIFE CYCLE

Every year the trees are pruned back by 25%, meaning the tree is completely renewed every four years. Bracu Estate prune the trees to let sunlight into the centre of the tree, allowing olives to grow on the inside as well as the outside, stimulating growth, good consistent fruiting, and generally healthier, more virile trees – great for producing olives.

HARVESTING & PRESSING

Bracu’s olives are picked at just the right time for optimal flavour and colour and are then processed entirely on the Estate the same day, using top-of-the range, Italian-made Pieralisi processing equipment.

The best production and flavour bases come from constant temperature. Extra virgin olive oil must be processed under 32°C, where it is both chemically and sensorially tested and verified. Bracu Estate aim for 25–27°C to achieve optimum production without compromising flavour. Depending on the year and flavour of the oil, they will sometimes process as low as 20°C. This assists with achieving big, green, strong flavours, but cuts yield in half.

PROCESSING

Bracu Estate’s on-site processing has major benefits to the final product:

- Their equipment is closed, so pulp and oils are not exposed to air and therefore do not begin to oxidise before packaging

- The process is continuous, so crushed olives are not left sitting in the factory awaiting emulsification

- All Bracu Estate oils are cold pressed to maintain all their original flavours and nutritional benefits

- Being processed entirely on the Estate means they have complete quality control from picking to packaging

It takes approximately three hours to process the olives from fruit to olive oil. The olives are first tipped into a hopper, conveyed through a leaf blower to remove any leaves, and then washed thoroughly in a water bath. From there, the olives go through a hammer mill, grating the olives to a pulp, which is augured into the malaxer where it is heated to 25°C for about 50 - 60 minutes to extract the oil from the pulp. The pulp and oil will then go through the centrifuge to extract any hard waste (pulp, skins, and stones). Lastly, the oil and water that is left will go through a separator to remove the water so that they’re left only with their award-winning extra virgin olive oil.

After separation, the oil is immediately polished to take out any impurities including small droplets of vegetable water or fine sediment; but that is not the end, they filter it too. All part of why Bracu Estate oil tastes so great.

SUSTAINABILITY

The entire production process at Bracu is carefully managed, but their commitment to quality extends even beyond the olives and includes a responsibility to the environment as well. Bracu Estate is not only carbon neutral but carbon positive, annually producing 500 times more oxygen than it absorbs from the atmosphere for its own operations. Olive waste is used as a composting base to assist with fertilising the estate and water used in processing the olives is recycled and used to irrigate the property.

The entire harvesting and production process, in addition to the sustainability measures, is a large undertaking, but it’s a key reason why Bracu Estate’s olive oil is considered among New Zealand’s finest.

Pre-order your bottle of their First Day of Harvest 2022 Extra Virgin Oilve Oil 500ml now from bracu.co.nz and experience the difference for yourself.

Facebook: @bracuestate

Instagram: @bracu.estate

latest issue:

Issue #120

As the days become shorter, and the nights cooler, the latest issue is perfectly timed to deliver delicious autumn dishes. From recipes using fresh seasonal produce such as feijoas and apples, to spectacular soothing soups and super-quick after-work meals in our Food Fast section, we’ve got you covered. With Easter on the horizon, we feature recipes that will see you through breakfast, lunch and dinner over a leisurely weekend holiday, and whip up chocolatey baking treats sure to please. We round up delicious dinners for two and showcase a hot new Korean cookbook before heading south to Dunedin to check out all that’s new in food and dining.The latest issue of dish is on sale NOW at all good bookstores and supermarkets – don’t miss it!